Let’s be honest. Production schedules rarely collapse from major disasters; instead, they break down when a single system lags, a network stutters, or a software update doesn’t work as expected—and just like that, everything comes to a halt.

For Omaha manufacturers, downtime isn’t just an IT inconvenience. It’s an operational threat that ripples through labor, production targets, shipping commitments, and customer trust.

The true operational cost of downtime isn’t just measured in lost revenue. It shows up in idle crews, rushed recovery decisions, strained supplier relationships, and long-term reputational damage — often from issues leadership never expected to halt production in the first place.

Table of Contents

Why Downtime Hits Manufacturing Harder Than Most Industries

Manufacturing environments don’t pause gracefully.

When IT systems slow down or go offline, production lines don’t “catch up later.” Labor stays clocked in. Equipment sits idle. Materials pile up. Schedules compress.

Even short IT disruptions — including slow systems, delayed file syncing, and intermittent network instability — can rapidly become costly for small and midsize businesses (SMBs). Independent research shows that even brief outages can cost SMBs between $137 and $427 per minute, which equates to $7,620 to over $25,000 per hour, once lost productivity, revenue impact, and recovery efforts are included.

For manufacturers operating with tight margins and continuous workflows, downtime multiplies fast.

The Real Financial Cost of Manufacturing Downtime

Across manufacturing sectors, downtime consistently ranks as one of the most expensive operational risks.

Recent industry data shows:

- $260,000 per hour is the average cost of unplanned manufacturing downtime across sectors

- Small manufacturers lose $137–$427 per minute during outages

- Manufacturers average 30 hours of lost production per month — more than 360 hours annually

- 60% of manufacturers report downtime costs exceeding $250,000 per year

Even localized Omaha manufacturers feel this pressure, especially those tied into agricultural, transportation, engineering, or industrial supply chains. One delayed shipment can jeopardize an entire vendor relationship.

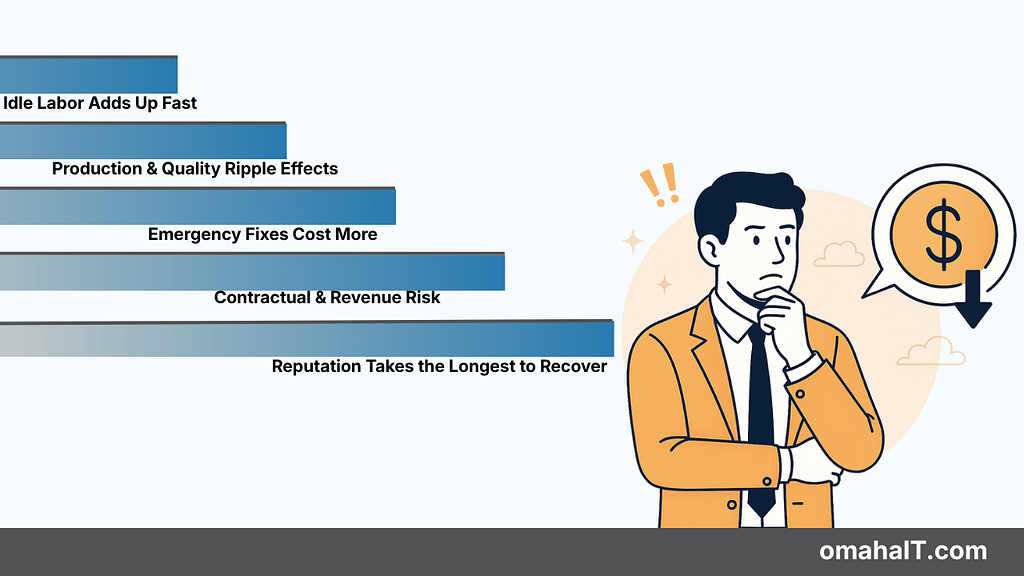

The Hidden Costs Leaders Often Don’t See

Most downtime calculations stop at “lost revenue.” That’s only part of the picture.

1. Idle Labor Adds Up Fast

If 25 employees sit idle for four hours, that’s 100 labor hours lost — before recovery even begins. Across manufacturing, productivity losses are often 2–3× higher than the actual repair cost.

2. Production & Quality Ripple Effects

More than half of manufacturing leaders report that downtime leads to missed shipping targets and quality issues. When reporting systems lag or troubleshooting drags on, bottlenecks cascade through the operation.

3. Emergency Fixes Cost More

Emergency repairs often cost 3–4× more than planned maintenance. Overnight shipping, rush labor, and temporary workarounds inflate what should have been manageable fixes.

4. Contractual & Revenue Risk

Missed deadlines can trigger penalties, withheld payments, or lost future contracts. In some cases, preventable outages can even complicate cyber insurance claims.

5. Reputation Takes the Longest to Recover

Nearly half of organizations report long-term reputational damage from downtime. For manufacturers working with enterprise or government buyers, regaining trust is slow — and expensive.

What Actually Causes Downtime in SMB Manufacturing

Downtime isn’t just about broken machines.

The data points to systemic issues:

- 67% of manufacturers rely on reactive maintenance

- 74% experience delays in reporting issues

- 72% rely on undocumented workarounds that mask real downtime

For small and mid-sized manufacturers specifically, the most common causes include:

- Hardware failures and misconfigured systems

- Software bugs and failed updates

- Network outages

- Cyber incidents, including ransomware

- Human error — responsible for 66–80% of incidents

These aren’t rare edge cases. They’re everyday operational risks.

Downtime as a Business Continuity Threat

SMBs often operate without redundancy.

One failed router, one server issue, or one misstep during an update can halt the entire plant. Unlike larger enterprises, there’s often no secondary system waiting in the background.

For Omaha manufacturers running lean teams and just-in-time processes, downtime threatens:

- Production commitments

- Workforce efficiency

- Contract obligations

- Customer relationships

- Long-term growth

At this point, downtime stops being an inconvenience — it becomes a continuity risk.

Why Proactive IT Has Become a Competitive Advantage

Across manufacturing studies, one pattern is clear: prevention costs less than recovery.

- Predictive and proactive maintenance reduces downtime by 30–50%

- Real-time monitoring cuts unplanned downtime by up to 25%

- Every 1% reduction in downtime can save specialized plants millions annually

Backup testing, system monitoring, and failover planning don’t eliminate incidents — they turn unknown disruptions into manageable events.

This is where IT shifts from “support” to operational protection.

What “Prepared” Actually Looks Like

Prepared manufacturers tend to share a few characteristics:

- Visibility into system health before failures occur

- Documented recovery plans that don’t rely on heroics

- Tested backups and known recovery timelines

- Clear escalation paths when issues surface

- IT aligned to production priorities — not just uptime metrics

The goal isn’t perfection. It’s predictability.

The Bottom Line for Manufacturing Leaders

One IT issue — a network outage, failed update, misconfigured system, or malware incident — can:

- Stop your production line

- Idle your workforce

- Delay shipments

- Trigger penalties

- Damage trust

- Cost hundreds of thousands per year

The operational cost of downtime is the most expensive unbudgeted expense manufacturers face — and one of the most controllable.

Not through more tools.

But through clearer visibility, intentional planning, and fewer surprises.

From Unplanned Disruptions to Operational Visibility

If downtime feels unpredictable in your environment, the first step isn’t a purchase — it’s clarity.

Understanding where risk actually lives inside your operation often reveals that many “unexpected” outages are anything but.

Frequently Asked Questions

1. How much does downtime cost manufacturers per hour?

Manufacturing downtime can cost anywhere from $8,000 per hour for SMBs to hundreds of thousands per hour depending on scale, labor, and production impact.

2. What causes the most downtime in manufacturing?

Common causes include hardware failures, network outages, software issues, cyber incidents, and human error — often compounded by delayed reporting.

3. Why is downtime more expensive for SMB manufacturers?

SMBs typically lack redundancy. One failure can halt the entire operation, with fewer backup systems to absorb the impact.

4. Can proactive IT really reduce downtime?

Yes. Studies consistently show 30–50% reductions in unplanned downtime with proactive monitoring, maintenance, and planning.

5. Is downtime mostly an IT problem?

No. Downtime is an operational issue with financial, workforce, and customer impacts — IT is just one part of the system.